Automation Integrators

AUTOMATION INTEGRATION

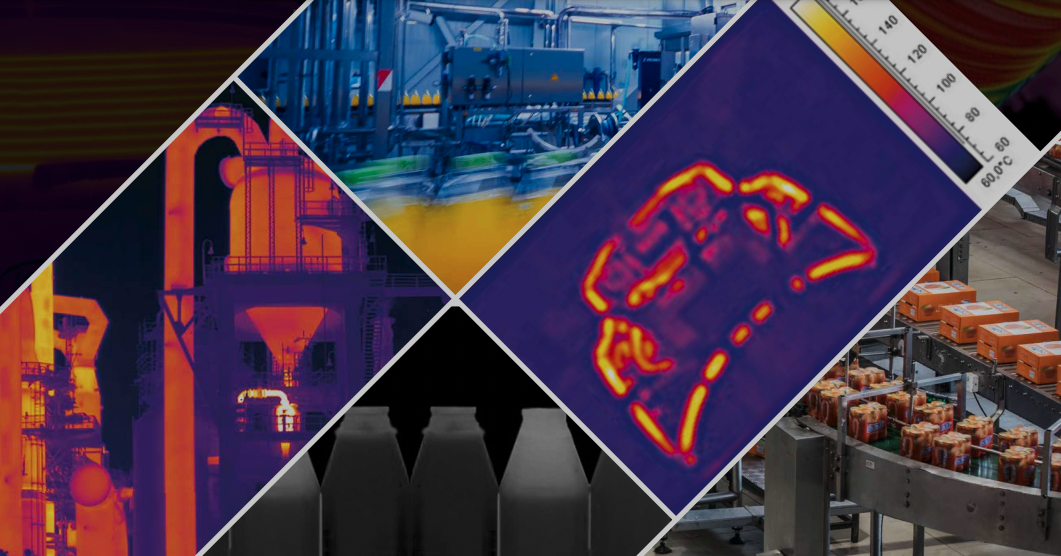

Get the Thermal Tools you Need for Safe, Efficient Manufacturing

FLIR high-performance, fixed thermal cameras can be mission-critical to a wide range of automation and industrial safety applications. In fact, new applications emerge every year as more industries identify a need for thermal imaging to:

- Find temperature problems before they lead to failures

- Prevent costly production stops

- Spot process anomalies that can flag dangerous situations early, improving safety in the workplace

How thermal tools fit into your existing production process isn't always intuitive; that's why the integrators who work with Teledyne FLIR ensure you have the right cameras, software, connections, and analytics to effectively monitor electrical or mechanical equipment, detect heat that could lead to a fire, or monitor processes and ensure quality throughout a production line.

How thermal tools fit into your existing production process isn't always intuitive; that's why the integrators who work with Teledyne FLIR ensure you have the right cameras, software, connections, and analytics to effectively monitor electrical or mechanical equipment, detect heat that could lead to a fire, or monitor processes and ensure quality throughout a production line.

Integration Partners

Partner Overview:

Viper Imaging is a FLIR Platinum Partner and leading integrator of thermal monitoring systems. Viper provides specialized software, rugged camera enclosures and PTUs, on-site commissioning & technical support.

Applications:

- Asset Condition Monitoring

- Early Fire Detection

- Steel Mill Refractory Monitoring

- Substation Monitoring

Industries Served:

Wood Products; Steel Making & Foundry; Oil & Gas; Chemical Processing Facilities; Heavy Industry; Power Generation, Distribution & Substations; and Commercial Properties.

Value-Add:

ViperVision Software

- Windows-based software suite that provides real-time monitoring, data acquisition, and imaging post-analysis of industrial processes.

ViperVenom Enclosures

- Up to Class 1 Div 2 (Class A & B)

- Air Knife & Purge

- Heated & Cooled

Partner Overview:

Emitted Energy engineers innovative manufacturing solutions, specializing in using infrared cameras and heating technology for production optimization. Increasing efficiency and improving product quality.

Applications:

- Process Control & Quality Assurance

- Asset Condition Monitoring

- Plastics Joining

- Injection Molding

- Adhesive Dispensing

- Thermoforming

- Packaging and Sealing

- Food Cook and Freeze

Industries Served:

Automotive; Plastics Industry; Machine Builders; Food & Beverage; Pharmaceuticals

Value-Add:

- TPMS (Thermal Process Monitoring System) - A complete process monitoring solution utilizing integrated thermal imaging systems. With real-time infrared thermal data collection and designed software intelligence, these systems depict out of control process limits with analytical trending for analysis and smart decision making. The systems can connect to your existing PLC’s to communicate with your machinery, thus gaining control of your process, preventing unwanted issues and wasted scrap.

- Machine Builder partnerships with complimentary run-off reports

Partner Overview:

MoviTHERM offers infrared thermal imaging systems for early fire detection, condition monitoring, quality inspection & and non-destructive testing.

Applications:

- Early Fire Detection

- Asset Condition Monitoring

- Plastics Joining

- Packaging and Sealing

- Quality Inspection

- Non-Destructive Testing

Industries Served:

- Industrial Laundry

- Waste & Recycle

- Manufacturing

- Plastic & Packaging

Value-Add:

- Cloud based (IoT) Solutions for Early Fire Detection & Condition Monitoring

- Intelligent User-Friendly Monitoring Dashboards with Mobile Connectivity

- Interactive MapVIEW for Situational Awareness

- FLIR MIO

Partner Overview:

Connors Industrials has over 100 years of steelmaking experience combined with multiple academic disciplines (mechanical engineers, ceramic engineer, journey machinist, thermographers and computer science software developers) to provide customized thermographic inspection/monitoring systems using FLIR technology to primary steel mills to support safety, production, and clean steel practices.

Applications:

- Slag Detection

- Refractory Monitoring

- Torpedo Car Monitoring

Industries Served:

- Steel Making & Foundry

Value-Add:

- Increase Safety & Predict Maintenance: LadleVision™ Thermal Imaging System for steel or iron ladles.

- The LadleVision™ system consists of networked fixed thermal cameras housed in extreme environment enclosures and a PC server with Connors Industrials LadleVision™ software.

- This automated thermographic solution allows for real-time nondestructive testing or monitoring of transfer ladles.

- Torpedo car vision.