Troubleshoot Breakdowns Before They Happen

![]()

CONDITION MONITORING

Electrical/Mechanical Inspections

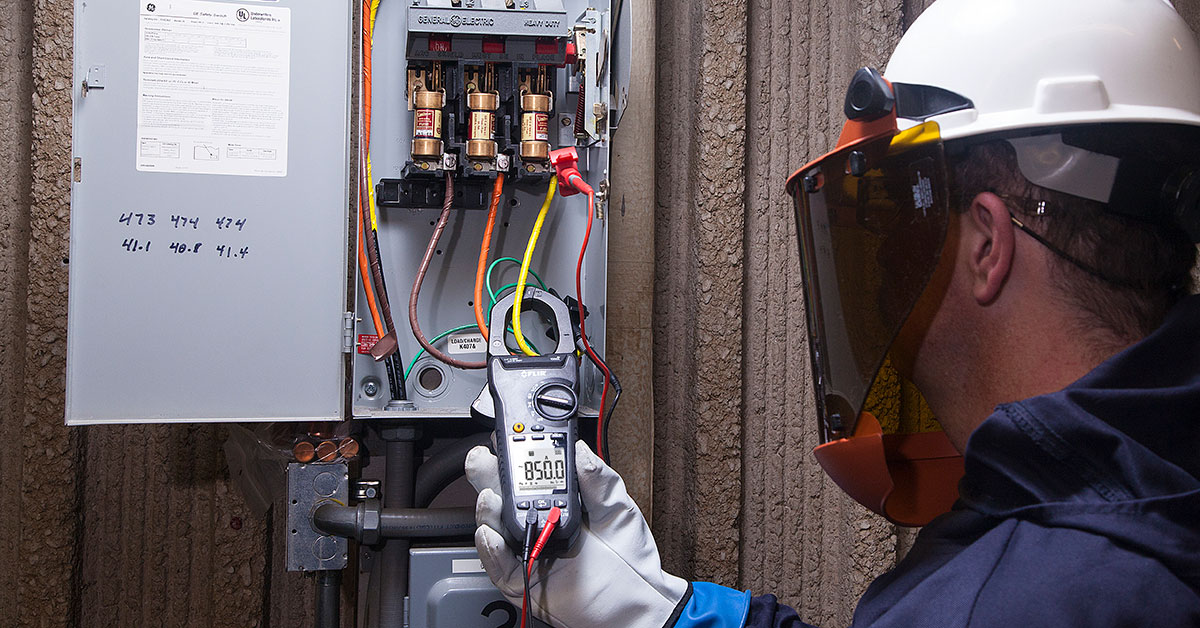

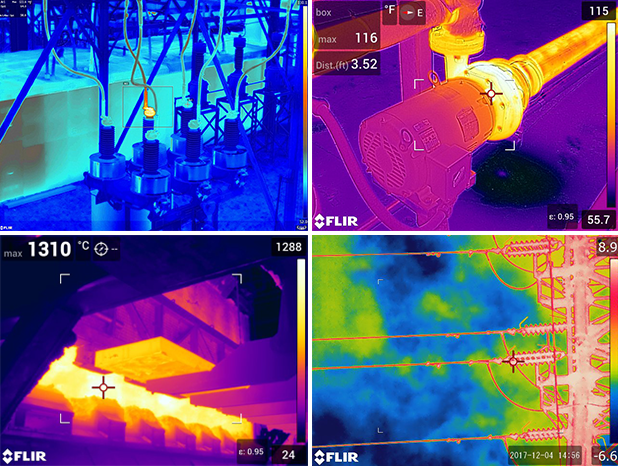

A solid predictive maintenance program can make the difference between meeting or missing production deadlines. Many companies incorporate thermal camera inspections as well as clamp or multimeter checks in condition monitoring inspections and to diagnose failing mechanical equipment or electrical systems.

FLIR thermal imaging cameras, FLIR Test & Measurement tools, and Extech meters allow technicians to inspect energized equipment safely—even at peak operation. Along with troubleshooting, our solutions can also help you optimize the production process and monitor quality control.

FLIR is a great tool for trouble shooting and preventative maintenance. It should be in every mechanic’s and electrician’s toolbox.

Electrician, Medium Enterprise Industrial Manufacturing Company

Source: TechValidate. TVID: FC3-4ED-6B5

Find it, Diagnose it, Fix it

Find it, Diagnose it, Fix it

See Initial Signs of Failure

FLIR thermal cameras and meters allow you to quickly scan large areas for hot spots on machinery or electrical systems that could indicate a potential problem.

Diagnose the Source of the Problem

With built-in features such as LoZ mode and in-camera temperature analysis options, FLIR's range of professional tools helps you quickly diagnose problems and get to the job of fixing them.

Demonstrate that it's Repaired

Thermal images provide visual proof a fault existed and was properly repaired. Including these shots and measurement data in your reports will help to document your work and increase customer confidence.

Recommended Solutions for Electrical/Mechanical Applications

FlexView® Dual FOV IR Lens (24°/14°) with Lens Case

For Txxx and Exx-Series Cameras; includes Lens Case

View Product

Beyond Compliance: Meeting and Exceeding NFPA 70B

The National Fire Protection Association's NFPA 70B guidelines now mandate thermal inspections every six months for critical electrical equipment that could endanger personnel. While meeting these expectations is important, going beyond compliance can improve uptime and worker safety, while allowing for a more streamlined workforce.

![]()

FLIR Thermal Camera Matrix

Compare FLIR's entire lineup of thermal imaging cameras with this quick, handy guide

![]()

FLIR IGNITETM

Improve your team’s efficiency and capabilities with the FLIR Ignite cloud solution. Directly upload, organize, and share images from your Wi-Fi connected FLIR camera. Keep your data safe in one place and easily accessible from any device.

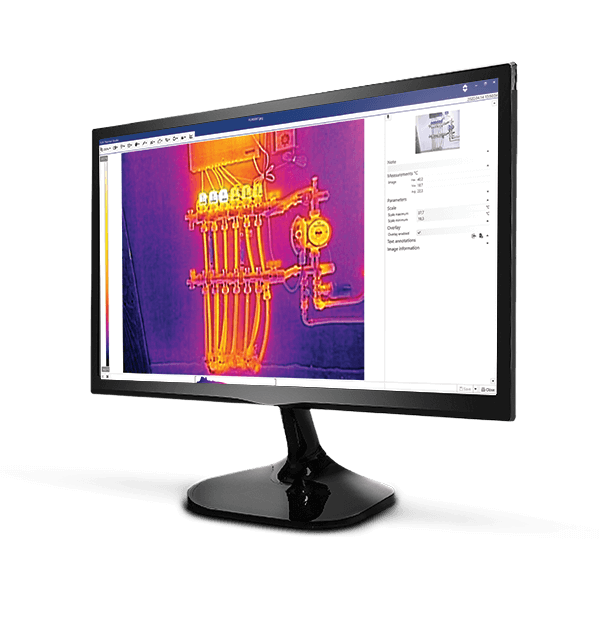

Give Your Customers Better Insight

For electric companies, professional reports go a long way toward helping your customers understand thermal camera inspections and the problems uncovered by our scanners. The advanced analysis and decision-making support offered in FLIR Thermal Studio Pro provides you with a rich set of measurement tools, batch processing, the ability to pre-plan inspection routes, and customized report templates.

Built for the Challenge, Measured for Precision

Advanced clamp meters offer advantages that provide better accuracy for more challenging jobs. True RMS clamps, like the EX623A clamp meter, ensure accuracy even when electrical waveform quality isn’t a clean sine wave. The EX623A comes with a built-in infrared thermometer and a laser pointer for pinpointing hot spots and a Non-Contact Voltage (NCV) detector, so you can safely check for live electrical current.

Target Problems Quickly with IGM™

Finding the source of an electrical failure can turn into a guessing game if you’re using a thermocouple or spot IR gun. FLIR IGM products combine thermal imaging with clamp meters or digital multimeters, so you can find hot spots visually and then quickly start on repairs.

get inspection information to the people you need

FLIR METERLiNK® App

The FLIR METERLiNK® app allows you to monitor a variety of environmental and electrical conditions simultaneously with the ability to connect with up to seven FLIR compatible meters at once. METERLiNK allows you to safely capture images and monitor hazardous areas remotely and in real time. Whether you're connecting several FLIR clamp meters, digital multimeters, or any of the new METERLiNK app compatible meters, you will be able to keep tabs on key readings around your facility and easily share them with your team.

The flexibility to inspect the way you want at a price you can afford

Discover More