Thermal Imaging Camera Keeps Fire Risk Under Control In Coal Pile Storage Site

Coal storage in large coal piles brings with it the risk of spontaneous fires. As always, prevention is better than cure. A thermal imaging camera from FLIR Systems helps to ensure safety at the Nástup Mines Cooperation in Tusimice, Czech Republic. The system provides a cost-effective solution for continuous, remote monitoring of temperatures in the coal piles.

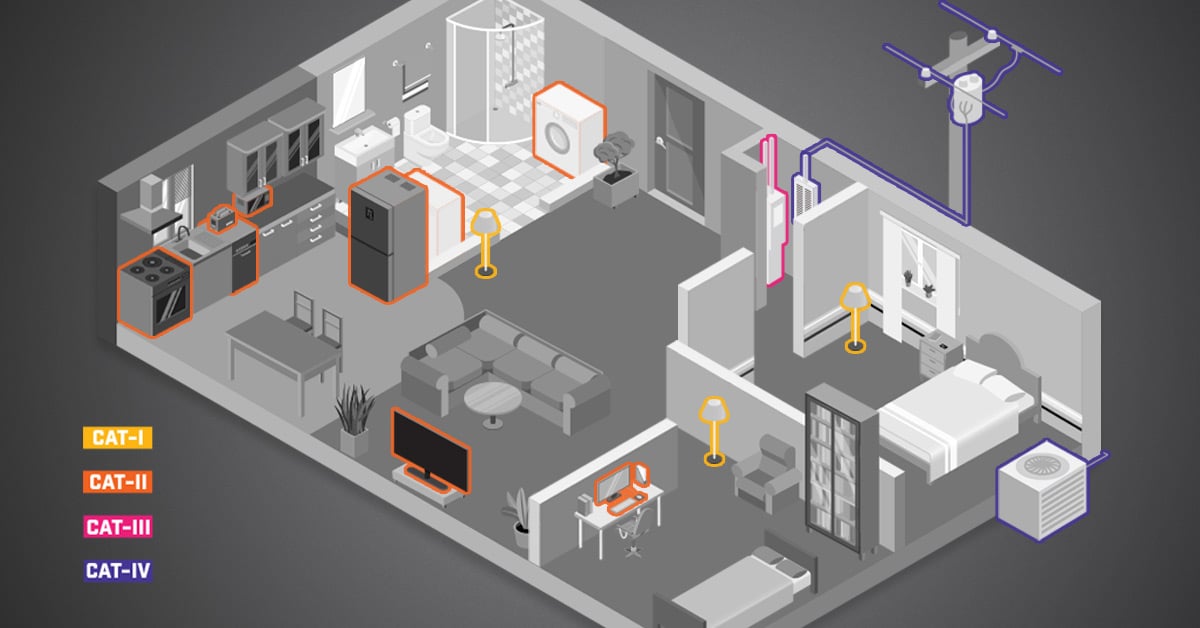

Bulk storage of any combustible materials leads to fire risk in many large storage areas such as waste bunkers, wood or paper stockpiles, as well cement and coal storage yards. Self-ignition usually starts within the bottom layers of a stock-pile as a result of temperature increases in the material. By continuous monitoring of the surface layers, hot spots can be detected in an early stage and action can be taken to prevent fires from breaking out.

Fully automated infrared temperature monitoring

A good example of an effective solution is the one supplied by FLIR Systems integrator ENELEX (www.enelex.cz) at the Homogenization Storage Yard SD of the Nástup Mines Cooperation in Tusimice, Czech Republic. For this location, ENELEX supplied a thermal imaging camera from FLIR Systems for continuous and fully automated monitoring of the coal pile. The large size of the storage yard means the use of a portable thermal imaging camera is not a practical solution for this critical task. Only a fully automated system is able to constantly monitor the hundreds of thousands of tons of coal which are stored at this site on an area of approximately 800 x 200 meters.

Extensive experience in continuous thermal monitoring

FLIR Systems thermal imaging cameras were selected because of the company’s extensive experience in a wide range of continuous thermal monitoring applications. These range from quality control on printed circuit boards right up to systems designed to operate in harsh industrial environments such as steel mills, glass production lines, waste treatment plans and other industrial processes.

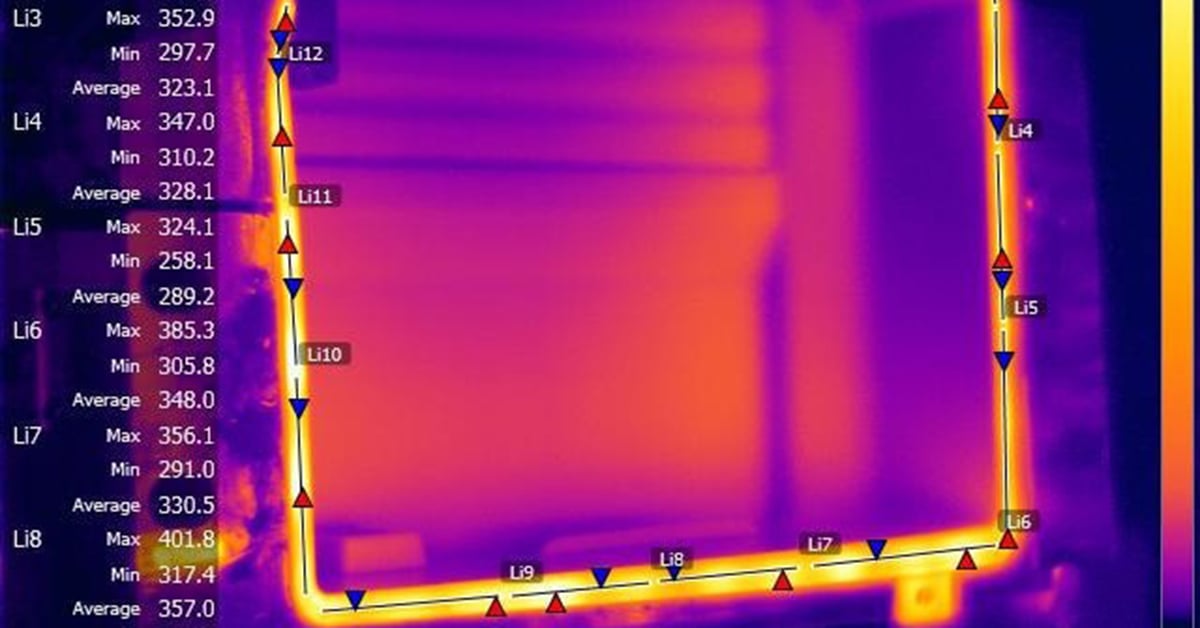

The system is based on the FLIR A310 thermal imaging cameras, which are mounted on five steel masts at strategic locations around the site. To ensure optimum coverage of the whole area, the cameras are configured to generate a direct alarm output to an operator if previously defined maximum temperature thresholds are exceeded. An acoustic alarm and a display alarm on a monitor will draw the operator’s attention to a possible spontaneous fire development.

The system allows for an accurate positioning and a detailed analysis of the critical location so that the hot spot can beextinguished and a fire prevented. Because of the extensive size of the storage site, the control and camera signals are transported by fibre-optic cables with a total length of 3 km from the camera mast to the control room.

Controlling fire risks at all kinds of sites

Over the past 10 years, thermal imaging cameras have been applied on an increasing scale for temperature monitoring and measurement applications, in addition to situations where their night vision capabilities are used. One of the areas where these cameras are being successfully applied is in sites which are subject to fire risk. In this way these cameras have enabled companies holding stocks of materials like wood, paper, plastic and wastes, as well as the cement and coal industries, to improve the safety of their plants and storage sites.

Safety of course means not only protecting the stored materials themselves, but also ensuring the safety of employees and others in the areas around the storage sites. In addition to that, there is also the risk of consequential damage that can be caused by fires, including loss of property, water damage resulting from fire-fighting and standstill of production lines. In view of these real risks, the cost of an automated temperature monitoring system using thermal imaging cameras is a modest and very worthwhile investment.

The FLIR A310 thermal imaging camera, a complete and cost-effective package

FLIR Systems' A310 thermal imaging camera is a complete and cost-effective package which is easy to implement in a wide range of environments. The system is supplied with all the components needed for installation:

- FLIR A310 thermal imaging camera, incorporating a patented uncooled solid state microbolometer detector

- Interfacing input/output box

- A flexible Software Development Kit, which allows the operator to preset and modify alarm conditions for previously defined areas within the camera’s field of view. These alarms control relay and analog outputs in the I/O box. For example, a relay alarm can be generated if the temperature within the defined areas falls below or rises above a predefined value.

As with all its products, FLIR Systems offers a complete range of accessory lenses, including close-up, wide-angle and telescopic, to match the requirements of specific applications.