Cherry Picking Vision

Reprint from the June/July 2012 edition of Imaging & Machine Vison Europe

Greg Blackman looks at how high-speed inspection systems are improving methods for sorting and grading cherries states.

Imaging systems are finding their way into the field, but they are still largely research orientated with very few systems commercialised. Where vision plays a much larger role is in factories sorting and grading crops like apples or cherries once they've been harvested.

'Most crops nowadays use vision systems for sorting in some respect,' states Roland Scheffer R&D manager at Ellips, a Dutch company manufacturing machines for grading and sorting fruit and vegetables.

Ellips is in the process of installing a vision system at a factory in the US sorting cherries. The site currently has 2,400 people sorting the fruit. 'If you can reduce that workforce by even half it's a lot of money saved,' he says, stating that the expense of manual labour is one reason for automating the process.

Inspecting cherries requires high-speed imaging, as the sorting machines run at around 30 cherries per second. This occurs on at least 10 lanes, equating to a rate of inspection of 300 cherries per second. Ellips machines scan the cherries with high-resolution cameras from FLIR. Ellips has developed its own operating system and algorithms to be able to analyse the images at those speeds.

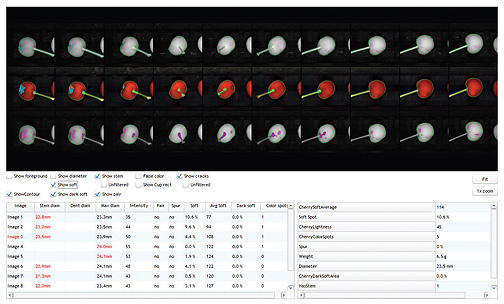

The system analyses the image to identify the contour of the cherry. It uses three cameras, one infrared, one colour, and a third monochrome version incorporating a filter to improve the contrast of defects, imaging in the infrared to do this. The three cameras inspect one lane, with each capturing 10 images per cherry (30 high resolution images in total) to cover the fruit's entire surface area as it rotates.

'The colour and infrared cameras are synchronised and the images overlaid onto each other to provide more information regarding blemishes or stem areas,' explains Scheffer.

The infrared image identifies the contour of the fruit – cherries can be very dark, but when viewed in infrared they appear light and can be picked out well against the background. 'Contour information is used to locate the stem, from which the system can determine the orientation of the fruit and measure its diameter at its widest part along the shoulder,' Scheffer continues. The cherry's contour is also used in the overlain colour image to calculate its area. This is important when determining the percentage coverage of a spot or blemish with regards to the total surface area.

The fruit are also graded by colour, in multiple classes ranging from light to dark. 'We also inspect spots on the cherry, soft shoulders, cracks, if the cherry is stemless or not,' Scheffer says. Producers want to grade the fruit and also sort out spurs, small cherries attached to other cherries.

'We need a lot of detail in the images since the cherries are small and when you're looking for defects you need high resolution,' Scheffer states. 'The FLIR cameras provide the resolution necessary for sorting the fruit.'

The requirements are getting more specific and there are higher market demands which have to be met, according to Scheffer. He comments: 'Cherries especially are difficult to inspect because the stems fly all over the place and can enter into an image on top of another cherry, which complicates the analysis. The algorithms will determine which stem belongs to which cherry and discard confusing images. Because it's rotating, every image is different and all need to be checked.'

The cherries are classified, directed into different lanes with air jets and are sorted further before arriving at the packing area.

As cherries are a natural product, Scheffer says that it's difficult to give percentage accuracies of the sorting. However, to give an idea, at the site in the US, the factory is currently using mechanical sizing systems, which have an accuracy of 40-50 per cent. 'Our optical system is at least twice as good for sizing the product,' states Scheffer, 'it provides somewhere between 80-90 per cent accuracy.' Also, he adds, the company weren't able to do colour sorting – colour and defect sorting were being done manually up until now with a lot of people.