Simplify MWIR Development with Neutrino Featuring InVeo Electronics

Integrating high-performance infrared cameras, lenses, and electronics are complex, expensive, and time-consuming development programs. Beyond the technical hurdles, managing conflicting supply chains and delivery schedules can add time, complexity, warranty conflicts, and cost to even the most conservative product introduction schedules.

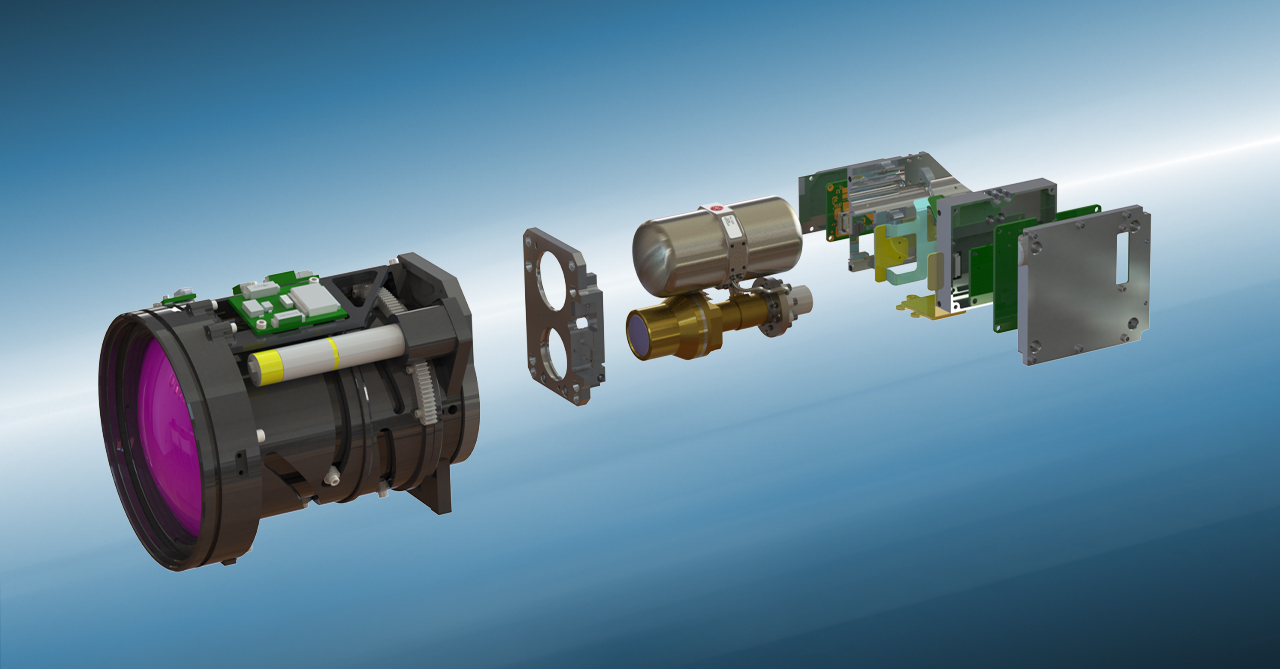

Teledyne FLIR’s Neutrino Ground ISR cameras reduce development risk and time-to-market while solving technical integration, performance tradeoff, and supply chain challenges. Neutrino Ground ISR cameras are an international traffic in arms regulation (ITAR) free, factory-integrated, turnkey solution for integrators developing intelligence, surveillance, and reconnaissance (ISR) systems. They combine Teledyne FLIR’s world-class mid-wave infrared (MWIR) camera modules and continuous zoom (CZ) lenses with market-leading image processing and control electronics from InVeo Designs, LLC (InVeo). Together, they allow integrators to create high-performance ISR solutions for new products and a direct path to upgrading existing designs.

AgileCore Electronics Integration

While Teledyne FLIR is known for its leading imaging performance, packaging the imaging engine and CZ optics together with the industry-standard AgileCore imaging electronics provide integrators with known and standard interfaces. This powerful electronics package provides crucial control I/O, data interfaces, and camera-to-lens communications in an easy-to-use solution from a small, nimble company renowned for its responsive customer service.

“Teledyne FLIR is proud to collaborate with the recognized leader in imaging electronics,” said Dan Walker, vice president of product development at Teledyne FLIR. “InVeo’s AgileCore platform is built on a completely programmable FPGA architecture that is always up to date with the latest features, creating a future-proof platform.”

To support the Teledyne FLIR Neutrino Ground ISR camera portfolio, InVeo adapted its proven AgileCore camera electronics platform to operate with the detectors and lenses manufactured by Teledyne FLIR. The basic AgileCore technology is robust, mature, and provides the core electronics subsystem for thousands of fielded thermal cameras delivered during the past decade. The AgileCore platform provides the following primary functions for the Neutrino Ground ISR series, and given its wide adoption, provides simplified integration and upgrade capability.

AgileCore Electronics - Key Functions |

|

| 1 | FPA Drive, Video Conditioning, Video Analog-to-Digital Conversion |

| 2 | Non-Uniformity Correction with 8 Operational Modes (Across Ambient Temperatures and FPA Sensitivities) and 2 Coefficient Sets at Different Zoom Positions (Minimizes Optical Artifacts) |

| 3 | Defective Pixel Filtering |

| 4 | Drifting Pixel Filtering |

| 5 | Noise Reduction Filtering |

| 6 | Local Area Processing for Superior Image Contrast |

| 7 | Digital Zooming |

| 8 | Automatic Gain and Level Control (AGLC) – Linear or Histogram Based |

| 9 | Standard SMPTE Video Generation (NTSC/PAL/HD-SDI) with Multiple Monochrome and Pseudo-Color Palettes |

| 10 | Digital Image Output via Camera Link/GigE Vision |

| 11 | Integrated Lens Control Including Manual Zoom, Manual Focus, and Autofocus |

“By developing specific-sensor-interface-rigid-flex boards to work with the Teledyne FLIR sensors and dewars, and by providing the proper mechanical support components, the proven AgileCore technology dropped into the Ground ISR line provides immediate product functionality and stability that would otherwise take years to develop and establish,” said Keith Johnson, director of engineering, InVeo.

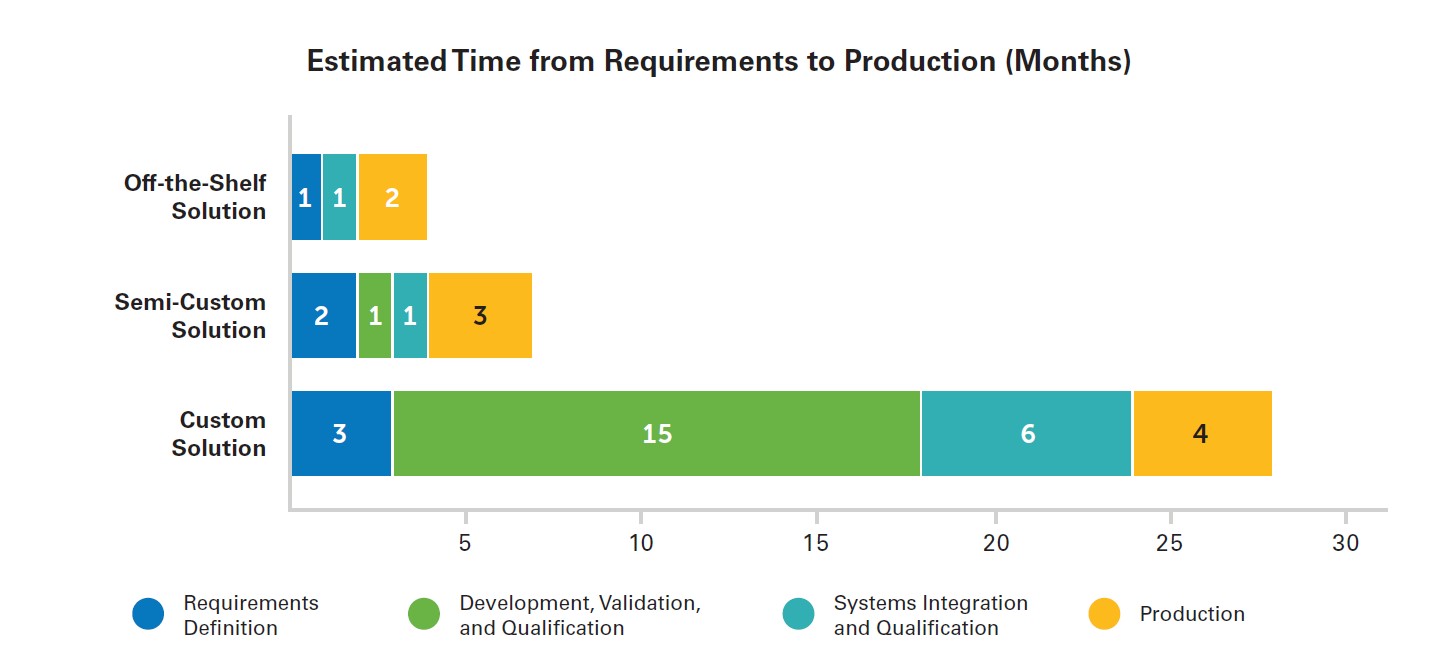

Faster Time to Market

One of the greatest risks to successful product launches and market penetration is timing. Missing a key launch window or event can turn an innovative product into one that gets lost in a forest of competitive offerings. The typical project timeline for a system integrator to develop an MWIR imaging platform averages 12 to 28 months when buying and integrating third-party commercial off-the-shelf (COTS) components. It can require even longer programs where developers need to design to specific customer requirements, such as with traditional government contract programs. The Neutrino Ground ISR portfolio solves these problems and cuts development time by months.

MWIR systems provide higher resolution and sensitivity compared to uncooled longwave infrared (LWIR) systems because they image a shorter waveband of energy, and by cooling the infrared detector to extremely low temperatures. This cooling has historically been complex and costly, limiting MWIR technology to military systems or high-end commercial applications. Recent advancements in high operating temperature (HOT) MWIR sensor technology improves the size, weight, power consumption, and cost (SWaP+C), making them less expensive while naturally increasing the demand for MWIR camera systems across industrial, commercial, and defense applications.

An MWIR imaging system consists of multiple subsystems. The zoom optics collect and focus the MWIR energy onto the detector and provide the field of view or optical magnification to the camera. The detector includes a focal plane array (FPA), readout integrated circuit (ROIC), and integrated detector cooler assembly (IDCA). Imaging electronics control the lens, FPA, and cooler to create an image. A development team must consider multiple variables, including pixel size, frame rate, vacuum packaging, and much more.

Development teams are challenged when acquiring and integrating subsystems from two or more providers. Reduced system performance and reliability are likely when integrating “standalone” components due to compatibility tradeoffs. This can also lead to efficiency loss and added complexity in the system development process, procurement, manufacturing, and eventual system support.

The Neutrino Ground ISR portfolio with integrated continuous zoom (CZ) optics was developed in response to this increased demand. Optical systems for HOT MWIR camera systems require lenses with f-numbers of 4.0 or faster to deliver high system modulation transfer function (MTF) and superior detection, recognition, and identification (DRI) capability. However, those demands come with challenges. Lower f-number lenses tend to be larger, have more components, and demand tighter tolerances within the lens assemblies themselves.

A significant innovation in the Neutrino Ground ISR is its CZ optical package. The optics for the Ground ISR portfolio were designed by Teledyne FLIR OSG (formerly New England Optical Systems (NEOS)). Numerous design-for-manufacturing (DFM) techniques were implemented to address these design challenges which has improved manufacturability, cost, and delivery for the optical projects.

The fully integrated SWaP-optimized lens system gives clear imaging throughout its smooth continuous zoom and focus range while being rugged enough to survive in the roughest environmental conditions. Teledyne FLIR uses sophisticated test equipment to align the camera and lens precisely providing industry-leading system boresight and boresight retention through the entire zoom range.

“Our design and manufacturing processes have been demonstrated effective on more than 1,500 optical design projects,” said Todd Stolberg, director of products for Teledyne FLIR OSG. “We mitigate design challenges such as MTF degradation over temperature, boresight drift, or unexpected image artifacts early in the design process to virtually eliminate these impacts to performance requirements, cost, and delivery schedules.”

This off-the-shelf solution provides optics that are precision-aligned in the factory for peak image quality, tighter optics-to-camera tolerances to ensure best-in-class boresight retention, simplified common electrical and software controls, and fewer moving parts. When developers work with a single solutions provider such as Teledyne FLIR to produce all the subsystems necessary for a complete platform, the results are shorter design cycles, streamlined procurement, increased reliability, reduced lead time, industry-leading warranty, and simplified support.

The Teledyne FLIR Advantage

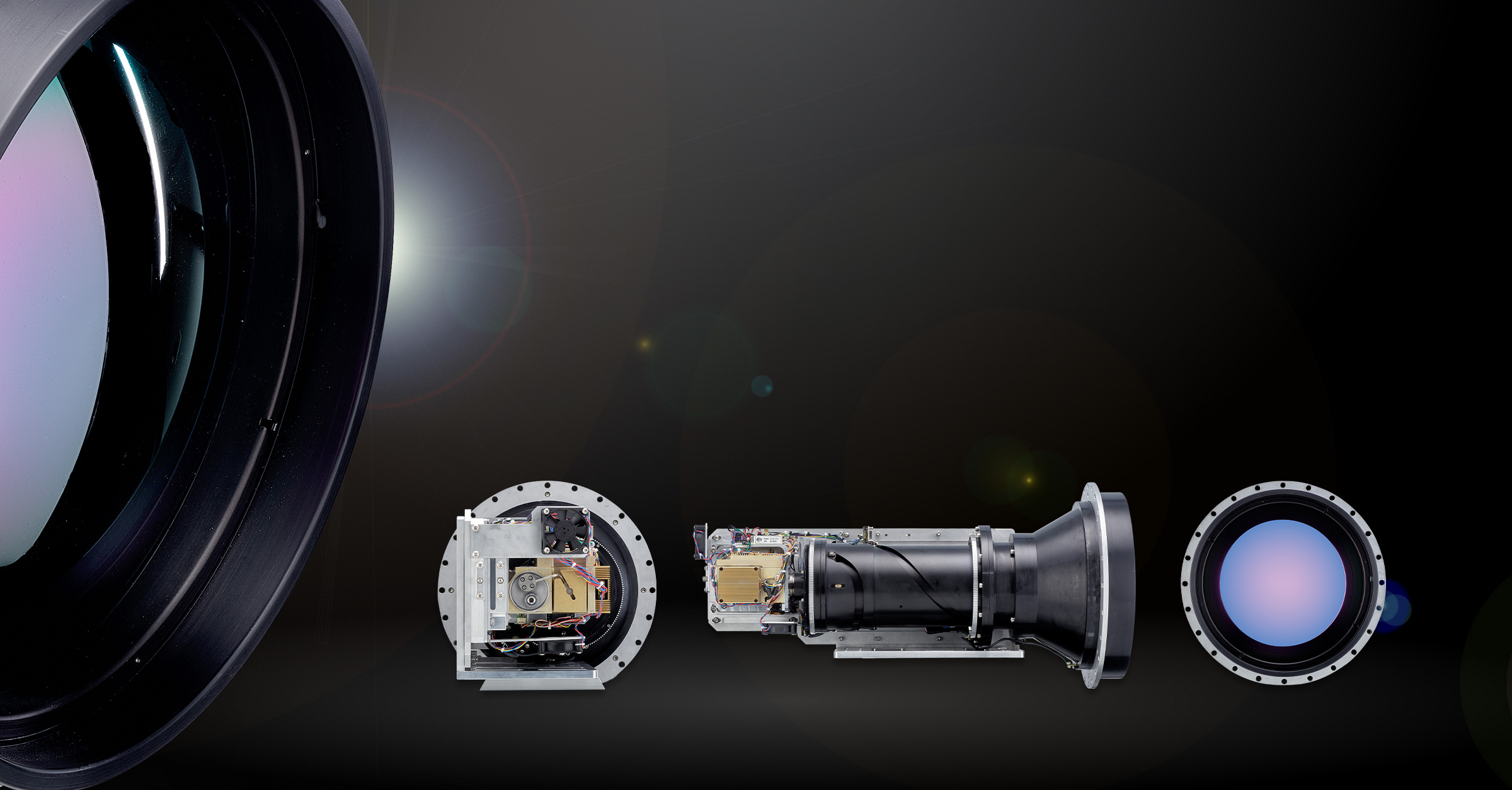

Teledyne FLIR is the first integrated solutions provider capable of supplying complete high-performance HOT MWIR camera modules and CZ optic assemblies through vertical integration. This includes detectors, optics, and one of the most crucial, life-limiting parts of a cooled MWIR camera system, the cooler. Neutrino Ground ISR uses a reliable linear cooler designed from the ground up for optimum performance and reliability to minimize cost while maximizing operational uptime. Compared to competitive offerings it has increased reliability and low vibration, creating an image in half the time. It also affords Teledyne FLIR to offer an industry-leading two-year warranty as it maintains a longer operational period in comparison.

The FLIR Neutrino Ground ISR camera core with integrated CZ lens and InVeo electronics delivers an integrator’s optimal solution for rapid product development with low cost and schedule risk. It sports uncompromising performance from vertically integrated, factory-assembled designs, and a full system optimized for size, weight, power, and cost.

Visit www.flir.com/neutrino to learn more.