FLIR Thermal Imaging Cameras Help Prevent Fires in Waste Incineration Plants

|

FLIR A315/A615 cameras combined with intelligent Waste Bunker Monitor software offers smart waste monitoring solution. Waste management is a key industry in most industrially developed countries throughout the world and is currently undergoing significant modernization and an increase in the use of waste energy. The whole cycle for the storage of waste, through sorting and recycling up to the effective conversion to electricity carries a high risk of fire or self-ignition, causing possible hazard for both personnel and the environment. To counter this, the Czech company Workswell has developed a complete thermal imaging solution, called Waste Bunker Monitor, designed for the continuous inspection of solid waste. For this solution, Workswell makes use of thermal imaging cameras from FLIR Systems. |

|

Workswell s.r.o. is a Czech technology development and trading company operating on the Central-European market. The company’s headquarters are based in Prague, Czech Republic. Its main activities include solutions´ delivery in the field of non-contact temperature measurement in many branches of industry. The company's customers are glassworks, foundries, cement plants, municipal waste incinerators, thermal power plants and more.

Waste managementThe amount of waste worldwide is still increasing. The Czech Republic alone produces approximately 3.5 to 5.5 million tons of municipal waste on a yearly basis.

Currently in the Czech Republic, 75% of the municipal waste is stored on landfills. Approximately 400,000 tons of that waste is thermally processed in municipal waste incinerators in Prague, Brno and Liberec, amounting to a total heat supply of about 2.3 million Gigajoules and a gross electricity production of about 18,000 Megawatt Hours. The advantage of thermal treatment of waste is, in addition to energy gains, the dramatic reduction in waste volume (approximately 10% or 15% of the original weight). For lots of waste the thermal treatment is practically the only appropriate method of disposal.

The incinerator in the Prague district of Malešice has been operational since 1998. The plant, fully named ZEVO Malešice (Equipment for Energy Recovery) takes care of the transformation of waste into thermal and electric energy. The acquired energy is used as heating of domestic water and heating of residential buildings.

Waste fires are a genuine threat in waste incineration plants and this is also true for ZEVO Malešice. The most common causes of fires at waste incineration plants are spontaneous chemical combustion of waste and hot particles given off by the vehicles that collect the municipal waste. A contributing factor to the risk of fire or devastating explosion is the increased concentration of methane, which is released from the waste during the decay process. In order to reduce the risk of fires, the ZEVO Malešice plant decided to invest in the Waste Bunker Monitor system from Workswell. The main goal of the system is to monitor the plant’s waste storage for emerging fires.

The waste at the ZEVO Malešice plant is imported into a storage tank. This tank is used for the homogenization of materials and to ensure sufficient reserve of waste so that the plant can be operated continuously, 24/7. In this case, Workswell has opted for two FLIR A615 cameras with a resolution of 640x480 pixels and with an 80° lens. These cameras monitor the storage tank for hot spots that indicate possible starting fires.

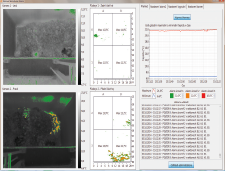

The Waste Bunker Monitor system from Workswell combines the non-contact measurement technology from FLIR Systems with proprietary software which presents plant operators with the critical areas that have an increased risk of fire.

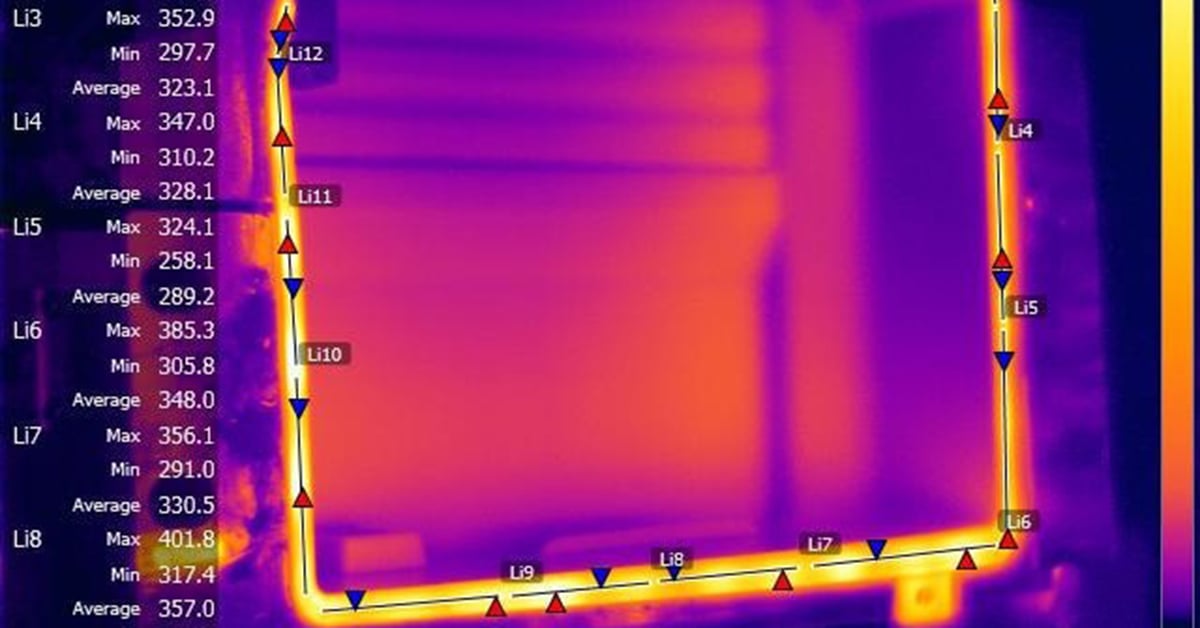

“The whole system is scalable and can consist of several thermal imaging cameras with high spatial resolution and with thermal sensitivity greater than 0.05°C," comments Jan Kovář, Managing Director at Workswell. “We have found that the FLIR A315 or FLIR A615 cameras are the best fit for our system. We always determine the number of cameras, their resolution and visual field of view in function of the smallest detectable temperature difference."

Control room monitoringThe monitored area is divided into zones in which the temperature values are evaluated several times per second. Consequently, the automatic system reports any area with an increased surface temperature to the crane operators.

“Luckily, we haven’t witnessed any fires yet at the ZEVO Malešice plant," says Jan Kovář of Workswell. “But we are very confident that the system and the thermal imaging cameras from FLIR will do a good job. We performed several tests before the actual deployment of the system and the results were much better than we expected.Next to that, the thermal cameras are very affordable, and thus they contribute to the overall cost-effectiveness of the Waste Bunker Monitor system. |