Compact FLIR Thermal Imager: Game Changer for Condition Monitoring

FLIR AX8 is a compact and affordable thermal-based condition monitoring solution for manufacturing companies and utilities

From process manufacturing applications to complex processes in utilities, it is important to guarantee uptime and proper functioning of all machinery. Condition-based maintenance systems help to maximize yield and quality, while decreasing unscheduled outages and maintenance and repair costs. Taiwanese technology integrator ADE Technology Inc. has now developed a compact and affordable condition monitoring solution for these companies, based on FLIR’s AX8 thermal imaging sensor.

Today, the majority of production companies in the semiconductor industry conduct preventive maintenance of critical equipment based on statistically derived and predefined intervals. While these practices have had relative success in managing equipment availability and product yield, the cost, both in time and materials, remains high. Sometimes, interventions are performed on machines that do not need it. Other times, maintenance actions that are missed will result in machine failures, bad product quality, and unscheduled downtimes.

“Maintenance is one of the key issues in modern semiconductor manufacturing,” says Wayne Sun, Sales Manager at FLIR Systems Taiwan. “In the past, condition-based maintenance and monitoring has been successfully adopted in utility companies and high-end industries, where costs associated with equipment downtime are critical for the companies’ bottom lines. But increasingly so, the semiconductor and electronics manufacturing industries, like we have here in Taiwan, are starting to see the benefits of condition-based maintenance and condition monitoring as well.”

Detecting heat

Condition monitoring is a way to identify features within the equipment that are indicative of the equipment health and of the potential degradation process. Heat build-up inside a machine is such an indicator, next to vibration and power consumption for example. The ability to predict machine and system failures before they happen can reduce costs and increase availability significantly.

ADE Technology Inc., based in New Taipei City, Taiwan, has been serving the industrial market for years with advanced video processing technology that seamlessly integrates with other industrial devices and other data sensor types in order to build various applications in the field of the Internet of Things.

“ADE knows the needs of utilities and manufacturing companies in terms of preventive maintenance very well,” says Wayne Sun. “Typical technologies that are used today for preventive monitoring are visual CCTV cameras and thermocouples. While both of these technologies have proven their use, they do have limitations in a preventive maintenance context.”

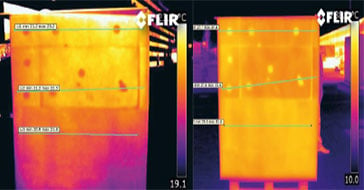

Visual cameras do have their use in 24/7 monitoring of equipment and can spot certain production problems in time, but they cannot see the heat build-up that is typically associated with impending equipment failures. To investigate equipment temperatures, thermocouples are often used as well. But this technology is also limited, as thermocouples only measure one point on the object at a time and do not provide a complete heat signature of the problem.

Thermal cameras

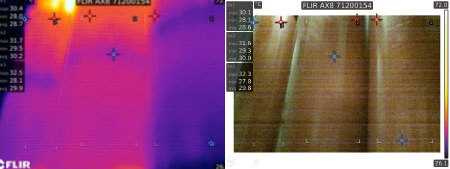

Thermal imaging cameras are used for condition monitoring and process control applications worldwide. Typical equipment that is monitored by thermal cameras includes high- and low voltage installations, turbines, compressors and other electrical and mechanical equipment. “Thermal cameras can see thermal irregularities in equipment that indicate failures and provide more information to production specialists and decision makers,” says Wayne Sun. “And what’s more, they can monitor problems continuously, without interrupting the production flow, and see problems before they develop into something worse.”

As a solution integrator and distributor for FLIR thermal imaging cameras, ADE knows the power of thermal imaging very well. The company has been integrating thermal cores and components into larger systems for many years and for many vertical markets. But it wasn’t until the introduction of the FLIR AX8 thermal imaging camera that ADE decided to build a dedicated condition monitoring solution for manufacturing companies and utilities: the T-Guard.

T-Guard temperature monitoring system

ADE’s T-Guard solution consists of FLIR’s AX8 camera and ADE’s AD-TG200 network video recorder and has been designed to help factories and utilities manage temperature-driven alarms triggered by the FLIR AX8 sensor, in addition to other sensor information like IP cameras, voltage measurement and environment temperature measurement.

Based on collected, real-time temperature data, T-Guard monitors the health status of equipment and generates critical impact alarms for a control center to follow up upon. The temperature information allows the system to send out differentiated alarms, according to the extent of the temperature raise and the criticality and imminence of the failure. T-Guard can manage up to nine FLIR AX8 cameras and can be used for enterprise-wide electricity management, solar PV management, Environment Control Systems (ECS), and many other applications.

Compact and easy to integrate

Installation of condition monitoring sensors into production equipment requires these sensors to be compact and easy to integrate. With the introduction of the FLIR AX8, integrators have exactly that. The AX8 combines a thermal and a visual camera in a small, affordable package, which only measures 54 x 25 x 95 mm, making it easy to install in space-constrained areas.

According to Jeffrey Chow, ADE’s General Manager, “The AX8 is definitely a game changer for traditional conditional monitoring. AX8 can be easily integrated with current-day automation PLC and NVR systems. With the FLIR AX8, the safety industry can finally dispose of an affordable smart sensor for thermal-based condition monitoring. Our T-guard solution leverages the advantages of the AX8, by integrating it with a network video recorder and alarm mechanism.”