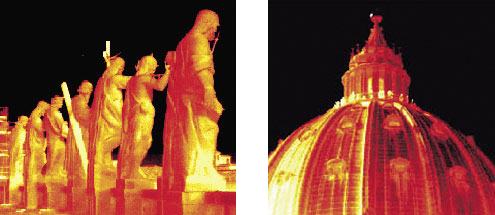

Façade of St. Peter’s Basilica in the Vatican is getting a face-lift with the help of infrared thermography.

Infrared thermography is being used to control the physical characteristics and to determine the state of preservation of the Façade of the St. Peter’s Basilica in Rome. This Basilica is widely recognised as the centrepiece of Christianity and the Vatican City.

In the year 323, a sanctuary, built in the form of a cross, was constructed to commemorate the crucifixion of the Apostle Peter. By the fifteenth century, the decay of this monument had progressed to such an alarming extent that plans were made to construct a Basilica. In 1548, the control of this project was given to Michelangelo. He built it in accordance with the plans created by Bramante of Florence, but strengthened the central piers to bear a dome measuring 123.5 metres high with an internal diameter of 42 metres.

Great emperors and most Popes are buried in the tomb of St. Peter. In 1606, Carlo Maderno, architect of St. Peter’s Fabbrica, won the competition to build the extension to the Basilica. In September 1607, Pope Paul V approved the model of Maderno’s Façade and, the following November, work began on the foundations. Construction continued until 1615 with the stucco covering of the vaults of the nave side aisles. The small domes of the side aisles were finished in 1616, the same year that the new choir was inaugurated.

Today, the Façade of St. Peter is maintained by ‘Fabbrica di San Pietro’, an organisation of the Catholic Church. This organisation permanently employs an elite group of architects, artisans and workmen. Only on rare occasions has the management of St. Peter’s agreed to seek assistance from specialists who do not belong to this select group.

The sole scientific partner of Fabbrica di San Pietro during the restoration of the façade of the Basilica of Saint Peter is EniTecnologie. This customer of FLIR Systems is headquartered in Rome. The appointment of EniTecnologie to develop and apply innovative techniques to this restoration project was quite an honour.

State-of-the-art infrared technology to restore historic monuments…

In November 1997, Mr. Giunta of EniTecnologie used a FLIR ThermaCAM™ SC 1000 on site. After seeing the enormous potential for use of infrared cameras for building restoration, he convinced EniTecnologie to purchase a camera. Since acquiring this ThermaCAM, Giuseppe Giunta has been focusing intensively on the restoration and conservation of artistic monuments.

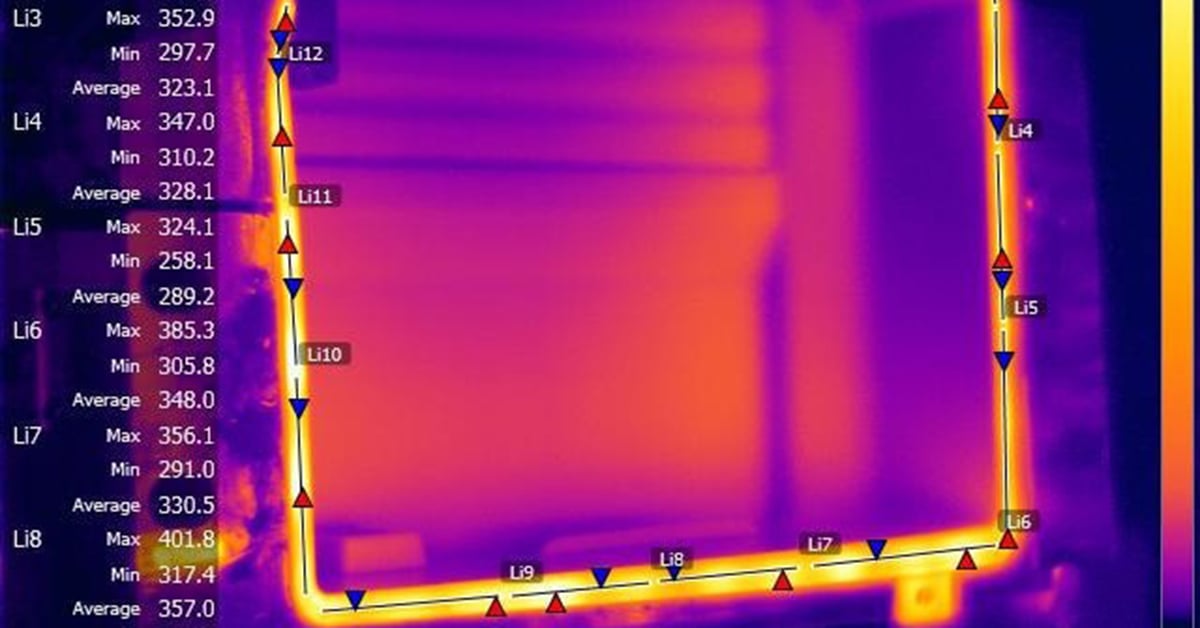

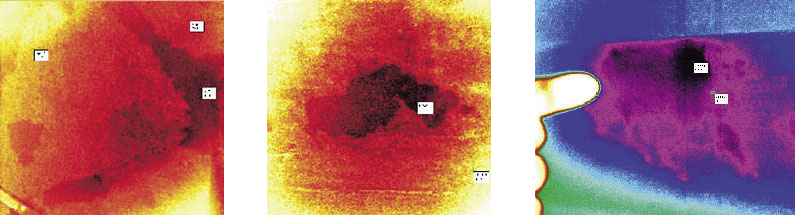

Thermographic techniques proved to be extremely effective in diagnosing the state of the Façade of St. Peter’s Basilica before the restoration commenced and in verifying the quality of the actual effort. The team from EniTecnologie was able to identify cracks, detachments of stucco from the stone surface and deposits of humidity that would otherwise have remained hidden.

The most significant use of thermography was in the evaluation of the stuccos where temperature differences of 0.5 °C were determined to be critical. Thanks to the high thermal sensitivity of the FLIR Systems ThermaCAM, the team was able to take IR images and to control the condition of approximately 50,000 stuccoes on the façade of the Basilica. Infrared thermal imaging also helped the experts to fine-tune a biocide treatment to remove the micro-organisms that plagued a large portion of the stone surface and to verify the effectiveness of this procedure.

… to everyone’s satisfaction

His Eminence Cardinal Virgilio Noè, president of Fabbrica di San Pietro, is very pleased with the result and expressed gratitude to the EniTecnologie team. “Due to the harmonic and proficient co-operation between the technicians of Fabbrica di San Pietro and those of the EniTecnologie group, the façade is about to be unveiled.” He stated that the operation was delicate and complex, extremely demanding, and that it was an important occasion to verify and confront many different restoration methods and techniques.

The project has been categorised as a success. Mr. Giunta recently told FLIR Systems, “Our thermographic work has been considered very innovative and of high quality. The result of our work has been presented to the management of the Louvre Museum in Paris and has caught the interest of the international press.”

The project team at Eni has met its commitments within a very challenging time frame. They concluded that: “infrared thermography, and in particular the FLIR Systems ThermaCAM, proved to be a virtually irreplaceable instrument in the various phases of the project,” and that their discoveries will prove, “invaluable for restoration work on historic monuments in the future.”

Eni is an integrated energy company, operating in the oil, natural gas, and petrochemicals industries as well as oilfield services and engineering, with a market presence in over 80 countries. EniTecnologie carries out scientific and technological research, concentrating its skills on the definition of innovative and environmentally friendly technologies.